Florida’s FDLE Alcohol Testing Program – Don’t Follow the 11D-8 Rules? Rewrite the Rule. Repeat.

“Only sometimes when we pick and choose among the rules we discover later that we have set aside something precious in the process.”

– Helen Simonson, Major Pettigrew’s Last Stand

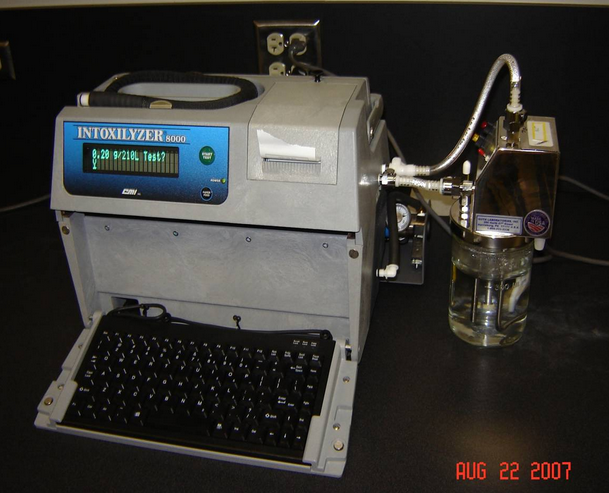

Matthew Malhiot recently wrote an article discussing how the Florida Alcohol Testing Program (ATP) violated Chapter 11D-8 F.A.C. rules when it failed to conduct department inspections after the Intoxilyzer 8000 breath test machines were “returned from an authorized repair facility.” The article is entitled “Florida-ATP Violates Chapter 11D-8 F.A.C. Rule.”

Matthew Malhiot was essentially the number three guy in FDLE-ATP – right behind Laura Barfield and Roger Skipper. Now he testifies as an expert witness or consultant in DUI motion hearings and trials. Laura Barfield also started a consulting practice and testifies for criminal defense attorneys.

The History of Chapter 11D-8, F.A.C., Revisions for Florida’s Intoxilyzer 8000

The article discusses the history of how the Chapter 11D-8 F.A.C. rule was revised in March of 2006 during the time that FDLE was going from the Intoxilyzer 5000 to the Intoxilyzer 8000. The revisions created two important problems that later arose.

Back in March 2006, during the time that FDLE-ATP was transitioning from the Intoxilyzer 5000 to the Intoxilyzer 8000, the rules were revised. After the revisions the rules required that the machine MUST have a department inspection completed after it was returned from an authorized repair facility.

Matthew Malhiot explains that the reason for conducting the department inspection after the machine was returned to the agency after repairs was that the process of shipping the machine could cause additional problems that could be detected during the department inspection.

At first, FDLE – ATP complied with the rule for the Intoxilyzer 8000 inspections. After all, the rule set in place a mandatory procedure that demanded that the department inspection MUST be conduct at the agency after the machine was returned from repair.

In the article, Matthew Malhiot makes that point that during that time, Department Inspectors were constantly traveling throughout Florida to conduct these department inspection at the agency. Matthew Malhiot should know exactly how the rule was being followed since he was one of those Department Inspectors traveling all around Florida to the county and city agencies diligently conducting Department Inspections.

Matthew Malhoit explains in the article that there were times that after the machine was shipped back to the agency from the repair facility that the machine would fail the department inspection. That failure would require the machine to be sent back to the repair facility for more repairs. He explains that the machines can and do sometimes break during shipping. The machines are often sent by common courier such as UPS.

Then in 2010, the FDLE-ATP decided to enact a new procedure. The new procedure had nothing to do with ensuring the accuracy or reliability of the machine. Instead, it was designed as a cost saving measure. Under the new procedure, after a repair the machine would be boxed up and sent by common courier to FDLE in Tallahassee where the repairs would be performed.

Then after the repairs, the Department Inspector would conduct the Department Inspection at FDLE instead of back at the agency. This new procedure saved money for two reasons. First, FDLE-ATP no longer had to send the Department Inspectors throughout the State of Florida. Instead, all of the Department Inspectors could work from one location and fewer department inspectors would be needed.

Secondly, the plan was for all of the repair to be made by the FDLE-ATP Department Inspectors instead of paying more money to have the repairs made by CMI, Inc., in Owensboro, Kentucky, or another repair facility such as Enforcement Electronic Services, Inc.

Many estimate that CMI, Inc., makes most of its profits from the “cost of labor” required for repairing the machine. For instance, when a battery has to be replaced, the machine was designed so that the battery was placed in a very inconvenient place that required the much of the machine to be taken apart to get to it. So CMI, Inc., certainly didn’t mind Florida boxing up the machines and sending them their way every time a repair was needed.

in 2010, FDLE-ATP put one part of the new cost-saving plan into place under the leadership of Laura Barfield. This first step involved relocating all of the Department Inspectors to Tallahassee. According to Matthew Malhiot, the second part of the plan was never fully implemented because the machines were still being sent for repairs at CMI, Inc, or Electronic Enforcement Services, Inc.

Violations for Not Doing Department Inspections at the Agency after Repairs

Matthew Malhiot’s article explains that between 2010 and July 29, 2015, “FDLE-ATP had NOT been complying with the rule which required that a department inspection be completed at the agency, upon the return of a machine from an ‘authorized repair facility.’”

Several different courts across the State of Florida started issuing rulings finding problems with compliance and that the problems were substantial. Only after those rulings did the FDLE-ATP dispatched a Department Inspector to each law enforcement agency, in the Florida Panhandle, to do the department inspections at each agency.

FDLE-ATP is not an “Authorized Repair Facility”?

As the pressure began to mount, FDLE just decided to change the rule. As of July 29, 2015, the FAC rules no longer define FDLE-ATP as an “authorized repair facility.” Therefore, after July 29, 2015, when a machine is shipped from FDLE back to an agency, it would no longer be required to complete a department inspection at the agency.

But didn’t that solution just create a more serious problem? If FDLE is no longer an “authorized repair facility” then how in the world are they going to save all that money by doing the repairs in Tallahassee instead of paying the repair facilities for the “cost of labor.” And what about those pending cases that involved FDLE-ATP actually repairing the machine?

No worries – FDLE also changed the wording in the rule from “repair” to “maintenance.” So we can expect the FDLE-ATP employees to around the state to start telling judges that the “repairs” are really just “maintenance.” Judges will be expected to bend over backwards to participate in this exercise in verbal gymnastics.

Matthew Malhiot makes the point that repairs would include such things as replacing batteries, replacing breath tubes, and replacing dry gas regulators. These are repairs and not simply maintenance because if a piece of the machine is broken and replaced then it is necessarily a repair. He gives the following example:

“When a breath tube is broken, the machine is NOT functional; therefore, a “repair” is required, in order for the machine to operate properly, allowing it to be placed back into service. Let’s look at some examples of what “maintenance” on an Intoxilyzer machine is. If the machine’s external “O” rings need changing, or say, the breath tube screen needs cleaning; that would be considered “maintenance”.

Nothing was broken on the Intoxilyzer, and they were simply maintaining the machine. Consider this, you have the oil changed in your car, would it not be considered “maintenance”? On the other hand, if the alternator on your car went out, you would most certainly need it “repaired”, in order for the car to function again.”

So the next round of motions begin as attorneys fight to have their client’s breath test excluded because a department inspection was not conducted at the agency after the repair and/or maintenance was performed.

Those who drafted the wording of the rule changes did a really bad job. When you change one rule it changes everything about the entire scheme – and the people who drafted these latest changes didn’t do a very good job at recognizing all the new problems that were created.

Free Consultation

Submit this form to request a free and confidential consultation with one of our attorneys.

Our Office Locations

Tampa Office:

Sammis Law Firm, P.A.

1005 N. Marion St.

Tampa, FL 33602

(813) 250-0200

New Port Richey Office:

Sammis Law Firm, P.A.

7509 Little Rd.

New Port Richey, FL 34654

(727) 807-6392

Clearwater Office:

Sammis Law Firm, P.A.

14010 Roosevelt Blvd. #701

Clearwater, FL 33762

(727) 210-7004