Problems with the Intoxilyzer 8000

The Intoxilyzer 8000 uses infrared spectroscopy to analyze the alcohol content of a breath sample after a DUI arrest. Infrared spectroscopy uses duel wavelength detectors of infrared energy to analyze for ethanol. The Intoxilyzer 8000 uses a pulsed IR source instead of a moving wavelength filter. It uses dual-wavelength for measuring alcohol in the breath sample at 3.4 and 9.36 microns.

The Intoxilyzer 8000 introduces an infrared light source into the breath sample blown into the instrument. The hardware then samples that light by using an infrared detector to measure the samples. Measurements are taken many times each second.

The process of measuring the samples produces hundreds of pieces of “raw date.” The “raw data” collected by the hardware is then interpreted by the software used by the Intoxilyzer 8000.

The result of that software interpretation is then provided on a printout reading which estimates the breath alcohol level.

Problems with Florida’s Intoxilyzer 8000 are often discovered from looking at the Intoxilyzer 8000 records and compliance issues with maintaining the Intoxilyzer 8000.

Attorney for Problems with Florida’s Intoxilyzer 8000

If you were charged with DUI and blew into the Intozilyzer 8000, then contact an experienced criminal defense attorney at Sammis Law Firm in Tampa, FL. We understand the problems with the Intoxilyzer 8000 and how those problems might have impacted your breath test.

Contact the attorneys at Sammis Law Firm for a free consultation to discuss the charges pending against you, the potential punishments, and the best defenses to those charges.

In a breath test DUI, your attorney needs experience handling these difficult cases and showing problems with Florida’s Intoxilyzer 8000 and your local agency’s breath testing program.

Call 813-250-0500 today.

Four Requirements of Each Breath Test

The Intoxilyzer 8000 was developed with four requirements that are aimed at ensuring the reading is scientifically reliable and accurately reflects the alcohol concentration.

- The person submitting to the DUI breath test must blow with sufficient flow;

- The flow must be maintained continuously for a minimum time;

- A minimum volume of air must be blown into the Intoxilyzer 8000; and

- The slope detector, which monitors the rate of change in the alcohol concentration of the breath sample must be satisfied.

Fail Safe Procedures used by the Intoxilyzer 8000

The software used by the Intoxilyzer 8000, in order to calculate a reliable reading, must utilize several fail-safe procedures.

Without viewing the “source code” and software that runs the instrument, it can not be determined whether the fail-safe procedures used by the Intoxilyzer 8000 result in an accurate reading.

These fail-safe procedures include:

- RFI Detect – whether a breath test result was affected by radio frequency;

- Interferent Detect Function – whether the reading detected by the infrared detector was caused by alcohol or by other substances in the breath sample;

- Slope Function – whether the alcohol found in the breath sample came from the defendant’s blood or from mouth alcohol;

- Purge Failure – whether a breath result was contaminated by failing to purge the previous result from the sample chamber;

- Ambient Fail Error – whether a breath result was contaminated by preexisting alcohol in the breath chamber;

- Control Tests – whether the machine was within calibration;

- In Range – whether each of the two BAL results were within 0.02 of each other;

- Volume Met – whether a sufficient volume of air was blown into the Intoxilyzer 8000 to obtain a reliable result (in Florida, the Intoxilyzer 8000 requires a breath sample of at least 1.1 liters).

Volume Not Met Problems on the Intoxilyzer 8000

The Florida version of the Intoxilyzer 8000 (which includes both the hardware and software that runs the machine), requires a breath sample of at least 1.1 liters. For any particular breath test sample, the machine should report to the breath test technician the warning “volume not met” when the breath sample is less than 1.1 liters.

If the machine is operating correctly, any breath test result that does not show a warning of “volume not met” should contain a sample with a volume greater than 1.1 liters. However, this fail-safe procedure does not work in many instances.

One well-documented flaw in the software can be demonstrated by the fact that the Intoxilyzer 8000 reported a volume of less than 1.1 liters but did not provide the “volume not met” warning. Without inspecting the “source code” and software it is impossible to determine the reliability of the reported volume measurement detected.

When questioned about this software flaw, officials for the Florida Department of Law Enforcement (FDLE) provided an explanation that seeks to minimize the impact of the flaw. The FDLE reported that the flaw was limited to cases in which a person continued to give a breath sample for longer than three minutes into the test.

By examining the test results, this interpretation of the software flaw is in incorrect because in some circumstances the machine would display the “volume not met” warning when the reported time for the breath sample was four minutes.

Another well-documented flaw in the software can be demonstrated by the fact that the Intoxilyzer 8000 reported a volume of more than 1.1 liters but still displayed the “volume not met” warning. If a problem exists with the reported volume of a breath sample, then the reliability of the corresponding breath alcohol level is also in question.

Perhaps the most problematic demonstration of a flaw in the software can be shown by the fact that the machine may report that no air was blown into the machine (0.0 liters) but still produce a breath alcohol level. Of course, if no sample breath is in the machine then no breath alcohol level could be detected. The only explanation for these facts is that a flow

Of course, if no sample breath is in the machine then no breath alcohol level could be detected. The only explanation for these facts is that a flow in the software is allowing the machine to return a breath alcohol level where none should exist.

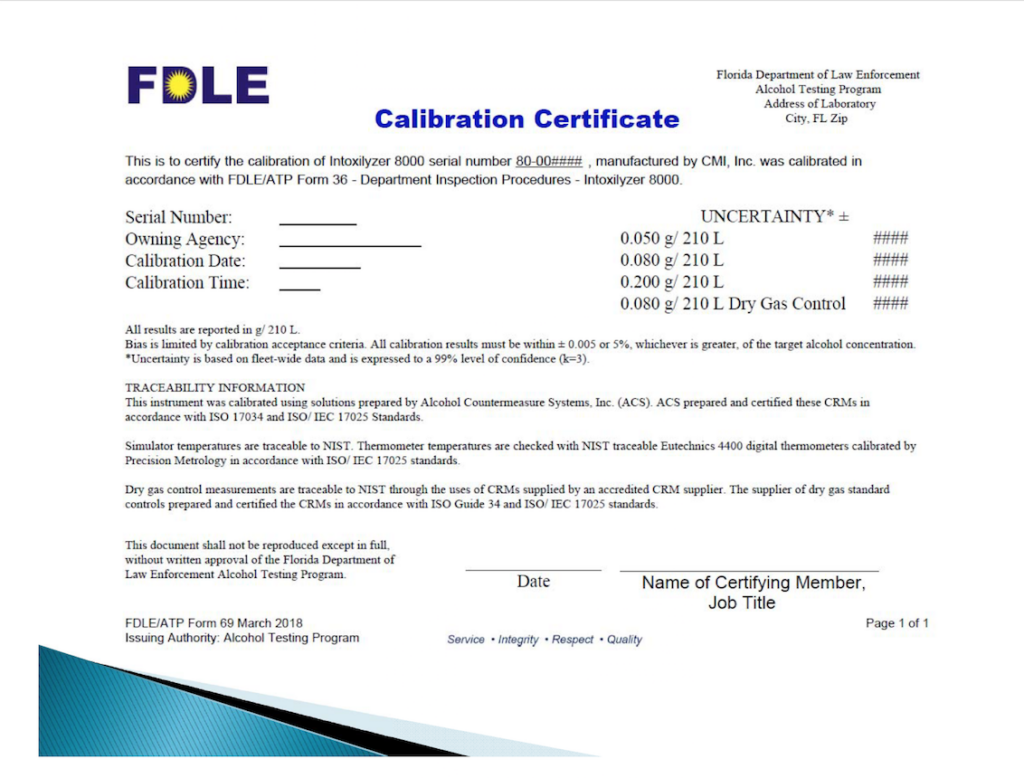

The Calibration Certificate for the Intoxilyzer 8000

Form 41 (ATP’s Department Inspection report) is set in formatting by Rule 11D-8. ANAB requires that Calibration results be accompanied by “uncertainty of measurement.” A form / report was created to meet this ANAB standard. This form does not affect the Department Inspection or change the information contained in the report.

The values listed simply explain that the values found on a Department Inspection will fall within a set range 99% of the time. Essentially, the instrument will read, in this case, a sample of 0.05 g/ 210 L accurately during a Department Inspection to within ±0.004 based on all inspections during the previous calendar year.

Free Consultation

Submit this form to request a free and confidential consultation with one of our attorneys.

Our Office Locations

Tampa Office:

Sammis Law Firm, P.A.

1005 N. Marion St.

Tampa, FL 33602

(813) 250-0200

New Port Richey Office:

Sammis Law Firm, P.A.

7509 Little Rd.

New Port Richey, FL 34654

(727) 807-6392

Clearwater Office:

Sammis Law Firm, P.A.

14010 Roosevelt Blvd. #701

Clearwater, FL 33762

(727) 210-7004

Our Attorneys